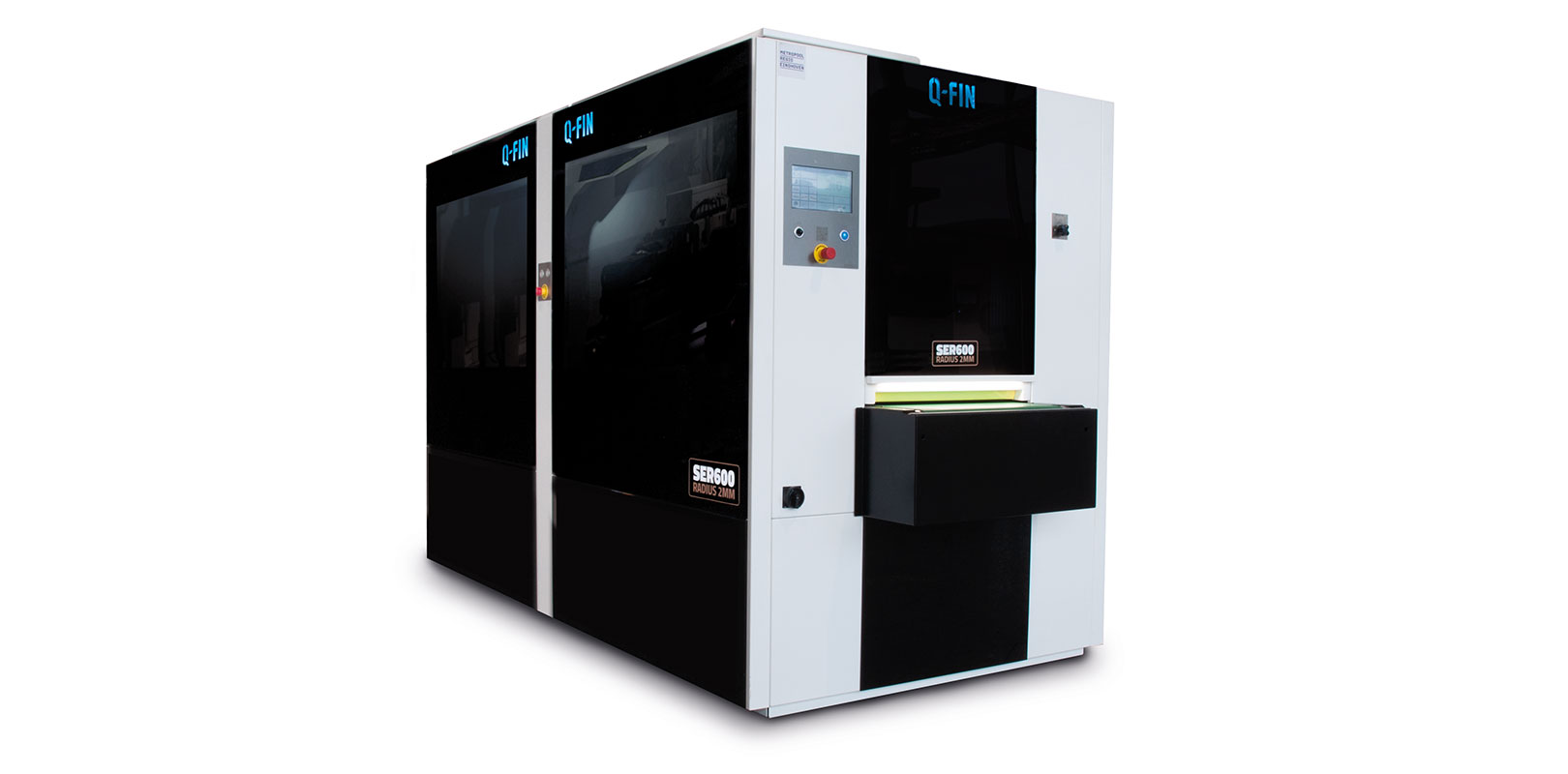

Q-Fin SER600 – Built for applying a 2 mm radius on sheet metal parts up to 600 mm wide.

- R=2 feasible in one pass

- Inner and outer contours rounded

- Complies with edge rounding regulations

- Better edge coverage when coating

- Different finishing processes in one pass

The SER600 is the latest development within the Q-Fin product range. This deburring and edge rounding machine is equipped with 5 processing stations: one grinding belt (1st station) followed by 4 oscillating brushes (2nd + 3rd station) and 2 rotating brushes (4th + 5th station). With this machine you can apply a large edge rounding (R2) on your sheet metal parts. The Super Edge Rounder is suitable for flat parts from 4 up to 40 mm thick and a maximum of 600 mm wide. This is the perfect machine for finishing sheet metal parts that need to be powder coated or galvanized.

Suitable for processing:

• Stainless steel

• Aluminium

• Steel

Unique system

Q-Fin introduces the SER600 Super Edge Rounder machine that can apply a 2 mm radius on cut parts in a single pass. This is not a standard machine that can also apply a large edge rounding on your product, but a machine that has been specifically developed to put a R2 on steel parts. This machine has five workstations and is therefore unique. One grinding belt upfront followed by four brush units. The combination ensures a perfect rounding of 2 mm on the product. The SER600 with magnetic conveyor belt is suitable for working sheet metal parts up to 600 mm wide, with a thickness of 4 up up to 40 mm. The length of the products is unlimited. Those who work with thin stainless steel

sheet metal parts do not need this machine, but a company that is producing (parts for) public installations on behalf of the government or parts for the petrochemical industry does. For products that need to be powder coated or galvanized, this is the ideal machine. If you want extreme finish results, you need to do something special.

If you want extreme finish results, you need to do something special.

Operation

The SER600 has 5 working stations. The first station of the SER600 consists of an abrasive head. The abrasive belt removes the burrs and incinerations marks from the product surface. You can determine the grain size of the abrasive belt yourself, depending on the height and hardness of the burr. The 630 mm wide abrasive belt is equipped with an oscillation system. This system has a unique, cantilevered construction and ensures that the abrasive belt remains stable. So, a lovely line grain finish is not a problem with this machine. Changing an abrasive belt is done within seconds.

The second and third stations consist of the so-called brush unit, equipped with 4 cross-rotating, oscillating disc brushes. These bushes give pressure from above and by doing so they remove the sharp edges of the product and break the edges. By placing special brushes on the first brush row, you can also remove the oxide layer or slag from steel products.

The fourth and fifth processing station consists of 2 oscillating round brushes. These work primarily on the sides of the product. In combination with the 4 disc brushes, this ensures a maximum radius on the edges of the sheet metal parts.

R = 2

There is a lot to do about a 2 mm edge rounding (r = 2 mm) on metal products. The question is whether such a substantial rounding is really necessary to prevent sharp edges, or more important to apply a protective layer on the sides (for example, when powder coating or galvanizing) which is as thick and strong as the layer on the rest of the surface.

Is it a general requirement or standard? Is it feasible everywhere? Is it affordable? The NEN-EN-ISO 8501-3 standard is, for example, prescribed by the Directorate-General for Public Works and Water Management. They have the experience that the conservation for example, on bridges has a much longer lifespan and therefore saves a lot of maintenance costs. When this standard asks for a P3, it stands for very thorough pre-treatment: “the surface is free of any visually noticeable defects”.

What matters is what customer and supplier agree on. They can agree on what they want, but a good edge coverage requires edge rounding. The Q-Fin Super Edge Rounder responds to this. This machine has only been developed and built to be able to achieve a Radius 2 mm on steel. Less is of course also possible, a R=1 or R=1.5 is in many cases sufficient, but R=2 in one pass is now also possible.