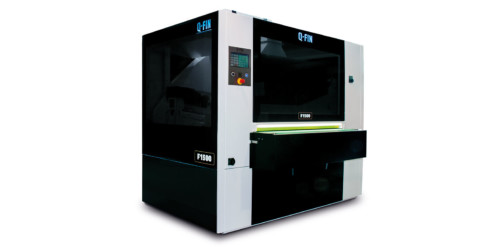

Q-Fin Deslagging Machines

Remove slag from your steel parts quickly and efficiently without any effort.

Heavy slag removal with hammer and chisel is time-consuming and physically demanding work for which Q-Fin has an automatic solution! Q-Fin introduces the DS600 and DS1200, two compact, stand-alone machines which easily remove slag from cutting parts in no time and prevent contamination in the deburring machine.

• Efficient and fast slag removal

• Heavy manual work is history

• Prevents dross being blown around

• Compact machine

• Can be integrated in every production line

Deslagging is a labour-intensive, dirty job which still often involves the use of a hammer and chisel. Or an electrically powered hand-held machine is used. Because of the heavy workload, for both the operator and the hand machine, these hand machines have to be replaced regularly. This causes high costs, an extra waste flow and possible health problems (e.g. HAVS) for the operator.

The DS600 and DS1200 have been specially developed by Q-Fin for the automatic removal of slag produced during plasma cutting or oxy-fuel cutting. This compact machine can be integrated in any production line. If a line setup is chosen, the slag is removed before the product enters the deburring machine, which then takes care of the edge rounding of the cutting part. In this way, the machine contributes directly to optimising the production process and improving work safety. The residual material (dross) removed during the processing of the product remains on the conveyor belt in the machine and falls neatly into the collection tray at the bottom of the machine. This molten metal can be disposed of as scrap in the appropriate container. If slag removal is integrated in a deburring machine, the machine will become seriously contaminated and there is a risk of damage from flying slag. By making the DS machine ‘stand-alone’, this is prevented. The DS600 and DS1200 has easy operation and optimal ergonomics for the operator.

This unique “DESLAGGING” machine is available in two widths and removes (heavy) slag from sheet metal parts up to 600 mm or 1200 mm wide by means of two robust slag discharging contact rollers. Because the hammer rollers rotate against each other and the pins are spread out, the product is hit at every point twice per rotation. The slag removed is discharged and the now flat product can then be transported by a roller table or driven conveyor belt to the deburring machine where it will receive its final finish.