Krasser Centurio – Fully automatic coil sheet cutting

After entering the type of material, length, width and number of pieces via the user-friendly touch screen, the Krasser Centurio will do the slitting and cutting procedure automatically and timesaving.

Our automatic and customer specific designed coil-warehousing system will transport the selected coil to the slitting and cutting machine and insert the sheet metal by our patented clamping system into the slitting and cutting unit.

The continuous length slitting is being done by up to 8 pairs of automatic positioned cutting rolls and the diagonal cutting by a guillotine shear.

Because of the high number of different materials our slitting and cutting machine is equipped with a material database. All machine adjustments for different materials (cutting clearance, the position of the straightening rolls, cutting depth etc) are being done automatically.

How it works

The coil to be processed is automatically transported and fed into the slitting and shearing unit from the virtually limitless expandable storage system. The automatic adjustment of the slitting knife with patented blade gap adjustment ensures precise strip widths and guarantees best cut quality. To change coil takes only two minutes, this process includes straightening and weighing the coil.

Once the coil is loaded into the storage system, all movement of the material occur automatically without any physical labour. Storage and transport damage to material surfaces and edges is therefore impossible. Lower scrap rates and higher surface quality is guaranteed. Coil loading and slitting processes run simultaneously whilst guarded by a safety fence. These features and benefits make the Centurio the safest and the fastest coil processing and slitting system worldwide.

“Centurio API” is an innovative user-friendly software interface which allows for easy upload and download of jobs, material data, weight information and much more.

Because the basic version includes a touch panel, inserting jobs or order queues is absolutely easy to handle. Through the use of an extensive database, all specific parameters are automatically assigned to the various cutting jobs.

Options

Labelling unit with sticker applicator

An industrial printer in combination with a conveyor, automatically applies labels to slits or blanks. The labels are positioned during the slitting process improving productivity. In combination with the “Centurio API” customer-specific data such as drawings, barcodes, length, width, material and order number can be imprinted on all labels. Through this function an enormous advantage for internal an external workflows is created.

Centurio-API interface

The Centurio API interface allows a trendsetting operation via upload and download of coil information, weight, jobs, or material data online! EPR software, optimization software, work flow schedules, or printing data are downloader within seconds via “Centurio API” point and click.

Roller shear for cross cut

Partial cut and crosscutting over the full coil width is easy to manage via liftable roller shear. The ability to shear from both sides improves offcut optimisation. In order to gain the full advantage of the “rotary shear for cross cut” we suggest the “Centurio API” interface in addition.

Automated film applicator

A brake motor controls surface speed, diameter of film-col torque and break resistance independently. Engaging and disengaging of the application is fully automated via touch screen or “Centurio API”.

System Configurations

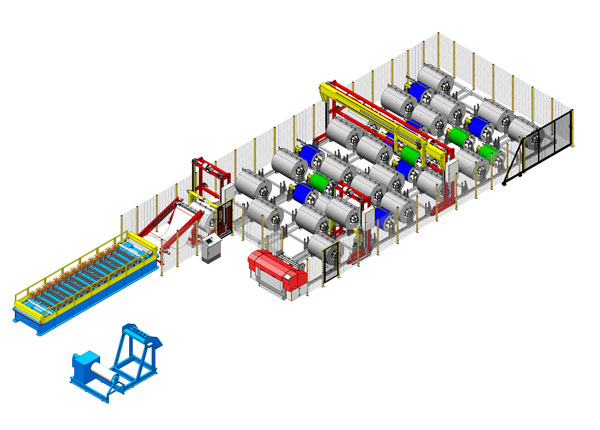

Extendibility is absolutely the biggest advantage of the Centurio coil processing system. Depending on requirements and budget, Krasser are able to offer single or multi row setups, up to five lines side-by-side. The flexibility in length and number of stations in nearly unlimited.

Centurio dual processing system

The Centurio storage system is able to supply several systems simultaneously with coils from the material warehouse. The advantage of using the same coils for multiple operations are obvious. The connection of rollforming lines, slitter and laser cutter in various combinations and in two working directions can be fully automated. Various external devices such as rollformers, lasers and punching machines can be connected to the Centurio storage system. Coil processing, feeding, and synchronisation all occur fully automatically. Safety fences provide the highest safety standards.

Various external devices such as rollformers, lasers and punching machines can be connected to the Centurio storage system. Coil processing, feeding, and synchronisation all occur fully automatically. Safety fences provide the highest safety standards.

The Advantages

- Safest system on the market

- Fully automated coil change

- Optimum protection of material

- Reduced scrap rate

- Best cut quality

- Fully automatic positioning of the slitting knife

- Software interface

- Automated labeling function

- Automated film applicator

- External recoiling possibility

- Flexible and expandable

Technical Data

| Krasser Centurio | |

|---|---|

| Maximum coil width | 1250 mm (49″) 1500 mm (60″) |

| Steel thickness range up to 400 N/mm² |

0.4 – 1.25mm (28 – 18 Gauge) Optional 1.5 (17 gauge) |

| Thickness range stainless steel 550 N/mm² | 0.4 – 0.9 mm (28 – 20 Guage) |

| Thickness range Aluminum (AlMg3) / Copper | 0.5 – 1.8 / 2 mm (24 – 12 gauge / 13 gauge) |

| Minimum strip width | 75 mm (3″) |

| Automatic straightening device | by 5 or 7 cylindrical rolls |

| Maximum cutting speed | 35 m/min (115’/min) |

| Cutting tolerance (gap) | Class ,m’ DIN/ISO 2768 (±0,8 mm/m) 1/32/yd |

| Automatic cut clearance adjustment | 0 – 0.3 mm (0 – 0.012″) |

| Length cutting | by up to 8 slitting rolls |

| Diagonal cutting | by guillotine shear |

| Maximum coil weight | 5,000 kg (11,000 pound) |

| Maximum outer diameter of coils | 1100 mm (43″) |

| Expanding range of coil shaft | 450 – 580 mm (18″ – 22.5″) optional 650 mm (25″) |