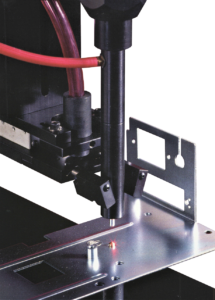

Auto-Sert Hydraulic Hardware Insertion Press

The Auto-Sert hydraulic hardware insertion press installs self-clinching fasteners into pre-punched, pre-formed, sheet metal parts. The machines insert many sizes of clinch nuts, studs, and standoffs manually or automatically.

The Auto-Sert 36″ Throat Machine offers all the features of the Auto-Sert 20″, and the ability to handle larger applications. It can be easily fitted with a moving brush table to both reduce operator fatigue and improve the overall safety. We think you’ll agree that these machines are on the leading edge of technology development in hardware insertion, and are unrivaled in design and quality.

Available in 7.5 and 10 ton capacity.

TECHNICAL SPECIFICATIONS

| Model | AS-7.5/36″ Throat | AS-10/36″ Throat |

|---|---|---|

| Tonnage | Minimum 350 lbs. Maximum 15,000 lbs |

Minimum 350 lbs. Maximum 20,500 lbs |

| Throat depth to back | 914.4mm | 914.4mm |

| Throat depth to top | 508mm | 508mm |

| Ram stroke | 152mm | 152mm |

| Hydraulic pressure | Minimum 40 psi Maximum 3,000 psi |

Minimum 40 psi Maximum 3,000 psi |

| Oil reservoir capacity | 45.42 liters | 45.42 litres |

| Heigh | 2007 mm | 2007 mm |

| Width | 914 mm | 914 mm |

| Depth | 1625.6 mm | 1625.6 mm |

| Weight | 1132.5 mm | 1132.5 mm |

PRESS FEATURES & BENEFITS

- Rigid Construction: 2” thick steel center mainframe.

- 20” & 36” Throat Depth Options: Design allows less restriction of movement around ram.

- Quick Change Tooling: Minimal tools needed for tooling change.

- Easy Access to All Machine Controls: Controls are convenient to operator from standing or sitting position. Increased operator awareness of control panel indications. Less operator fatigue.

- Uniform Hydraulic Pressure by Design: No variation in pressure from heat build-up. Hardware installed uniformly in thin, soft aluminum parts at low-pressure range down to 350-lbs. force.

- To install ¼-20 studs in stainless steel, the Auto-Sert press has the capacity – with power to spare.

- Reliable Safety System: Redundant safety system internally monitored by a micro-controller.

- Very sensitive pressure sensing device used, plus ¼” window of safety before full tonnage is applied by press in manual operation. Operator can work faster with confidence.

- Digital Countdown Counter for Fasteners: Keeps track of number of hardware in each chassis or part, with automatic reset feature. Operator is alerted to hardware forgotten in part. Better quality control.

- Digital Counter for Part Production: Keeps track of part production to save operator time. Has reset button, automatic record.

- All Auto-Sert presses are ETL, CE and CSA Certified to NFPA 79 Standards.