Resato will present the new Flex-zone at the Euroblech 2014.

After winning the Public Award in Utrecht this year, it’s time to show this to a bigger audience.

Up to 40% increase in waterjet production hours with Resato’s new Flex-zone.

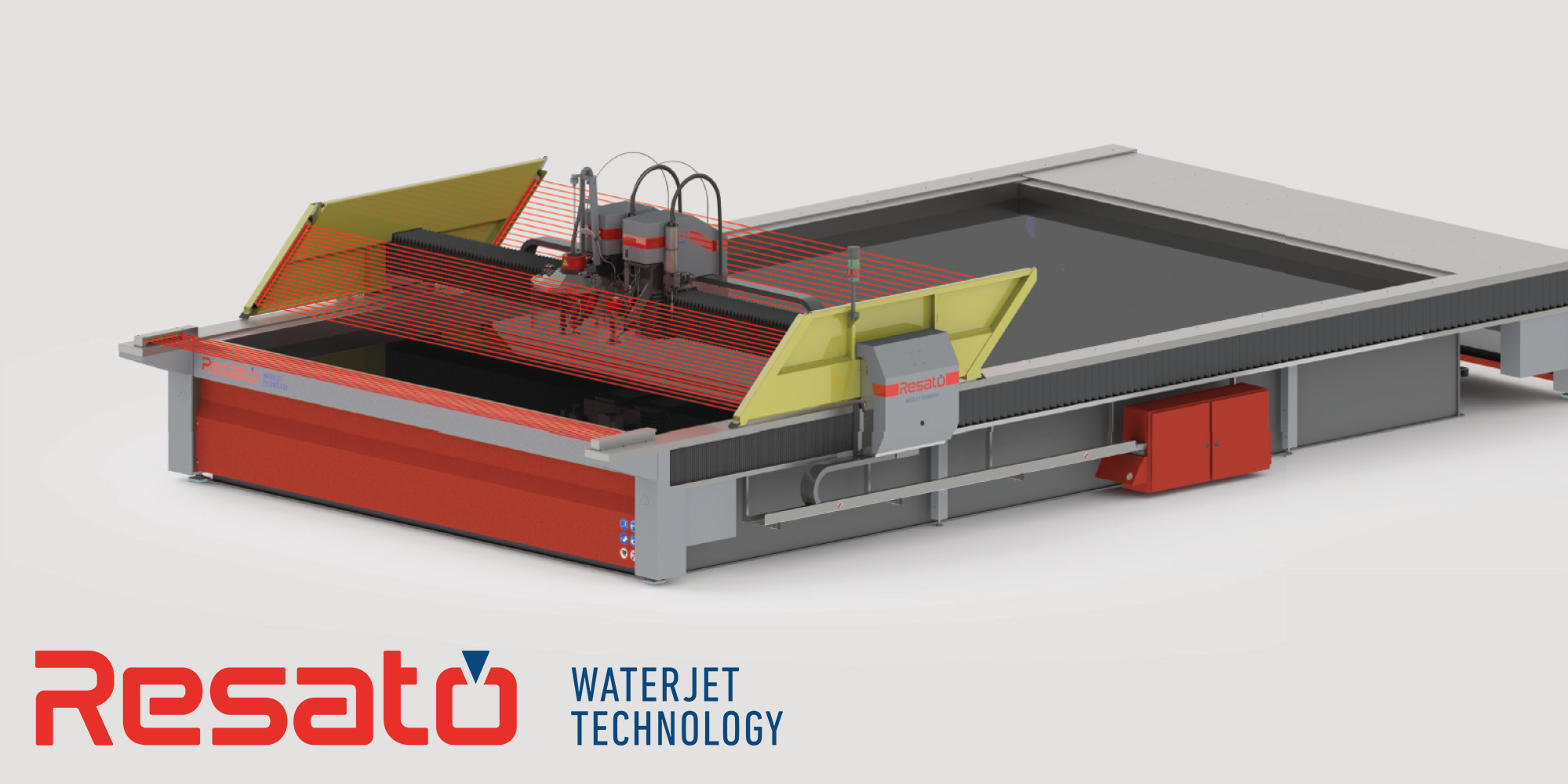

Most traditional waterjets use light screens surrounding the cutting table to comply with safety regulations.

Resato has found a way for these light screens to be placed onto the bridge where they move along with the cutting heads, to provide necessary safety only where needed: in the cutting zone. The Flex-zone option allows safe loading and unloading of material while the waterjet cuts.

This reduces downtime to a minimum, rendering an up to 40% increase in productive hours.

With this innovation Resato further reduces the competitive gap between waterjet cutters and both laser cutters and plasma cutters. Besides new customers, existing customers can benefit as the Flex-zone option can be retrofitted to most ACM cutting tables due to the unique modular concept of the ACM-line.

Resato will also have the ACM2040-2 on display, equipped with all options such as 2,5D cutting head, drilling, printing and connected through a second console with the programming software.

Resato – The hardest thing we cut, is time!

VISIT RESATO DURING THE EUROBLECH AT HALL 12, STAND B09