There are a number of angle measurement systems on the market, but not all are created equal. Below we will look at the SafanDarley E-Bend L Blue and what separates it, from other systems.

One of SafanDarley’s latest innovations is the E-Bend L laser angle measuring system, which uses two blue laser sensors. The sensors are fully CNC-controlled, extremely accurate and guarantee a finished product with the greatest angular precision.

E-Bend L Blue

The highest level of accuracy from press brakes can only be guaranteed if you take into account the influences of the actual material. The angle may vary from the programmed value because of a variation in sheet thickness and material qualities, such as tensile strength and rolling direction. In practice, this results in a loss of time and material. The E-Bend L-blue enables continuous measurement of the product angle while bending. This involves the use of a camera with a built-in sensor, which continuously provides information about the angle of the product. In this way, variations in sheet thickness, rolling direction, etc., are corrected automatically. This system provides major benefits for both one-off and batch production. The first part is a perfect part with the greatest angular precision.

Blue laser light

E-Bend L Blue uses the latest development in laser light technology. Instead of a red laser, this system uses blue laser light. The wavelength of red laser light is almost identical to that of natural light, which in effect means that the measurement is always susceptible to fluctuations. The new generation of E-Bend L-Blue has blue laser sensors. The blue light spectrum is much easier to distinguish from “natural” light, so reflections and sunlight no longer affect the measurement. At the same time the new sensor, in combination with the new control platform on the E-Control, can carry out many more measurements per second. As a result the system is faster and more accurate.

Working method

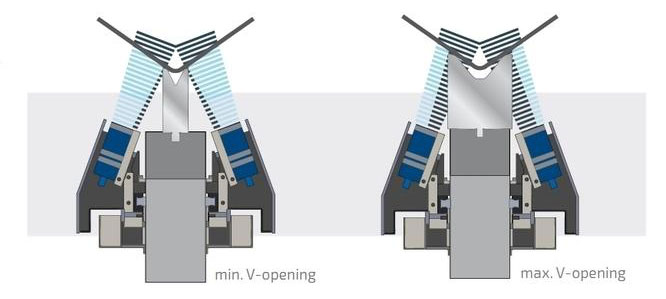

The system consists of two laser sensors, one on each side of the table, which are CNC-controlled from the E-Control. The system continuously monitors and corrects the position of the Y axis on the basis of the current product angle, thereby guaranteeing a finished product with the greatest angular precision.

The E-Bend Laser can be used in three ways

- Angle measurement with active measurement of the springback

- Angle measurement with database

- Angle measurement with learned bending

In the case of angle measurement with springback, the E-Bend Laser measures at one or three positions during the bending process, corrects the crowning and alignment (Y1 & Y2), and measures the springback. This data is then stored in the database.

In the case of a database angle measurement, the system uses the database. This database contains a broad spectrum of springback values for a wide variety of materials. This information is used to calculate corrections in advance to obtain a correct angle. The bending process can therefore take place more quickly and with no loss of production time.

Specifications

- blue laser sensors

- ultra high-speed sampling/output

- V opening of V=6 mm to V=100 mm

- measuring range from 160° to 45°

- independent of die

- easy maintenance

- no reference or calibration required

- works in combination with standard tools wh=100 mm

- can be used with the CNC-controlled W-axis in any lower beam position